PUMP

HEAD CALCULATION

Pumps are the heart of a water supply

system which conditions the flow of the fluid from ,one place to another which

have a head to overcome.

Pumps basically act as a catalyst which

enhances the process of the fluid transfer within shortest period of time.

Before taking pump into consideration it

is necessary to understand what is head and why it is necessary ….?

Well lets understand the concept of pump

head…

Well head is the height of space, where the

fluid is to transfer.

Basically if we want to submit the fluid

from ground to top of a building we measure the vertical height of the pipe fluid

which has to be lifted that measured height may called as head.

Well lets understand the head deeply

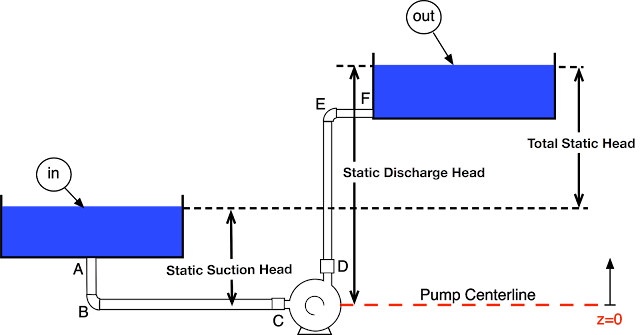

Suction head : well

this is the height which is measured as shown in the figure from centerline of

the pump till the rim of water in the tank.

Discharge or Delivery Head: height

from centerline of the pump to the rim of the tank which has to be discharged

as shown in the figure.

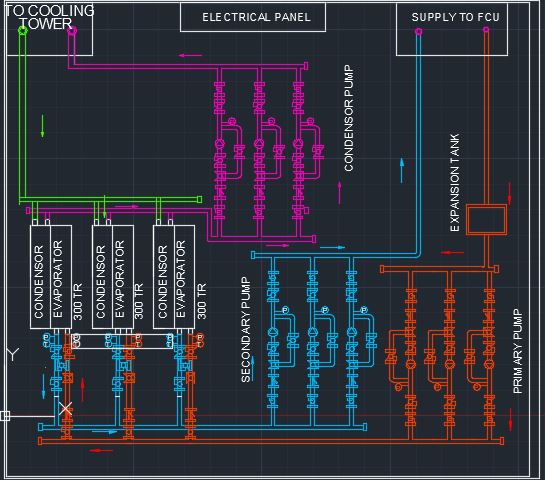

Well this the plant layout of pumps

BASICALLY THERE TWO PUMPS

PRIMARY PUMP

´ THE PUMP WHICH SUCKS THE WATER FROM AHU/FCU TO THE

CHILLER UNIT.

´ THIS PUMPS SUPPLIES HEAT ABSORBED WATER FROM AHU AND

SUPPLY TO CHILLER UNIT .

SECONDARY PUMP

´ THE PUMP WHICH SUCKS THE WATER FROM CHILLER AND SUPPLY

TO AHU/FCU .

´ THIS PUMPS SUPPLIES CHILLED WATER FROM CHILLER TO AHU

FOR COOLING EFFECT.

CONDENSOR

PUMP

´ THE PUMP WHICH SUCKS THE WATER FROM CHILLER AND SUPPLY

TO COOLING TOWER .

´ THIS PUMPS SUPPLIES CONDENSENED WATER FROM COOLING TOWER

TO CHILLERS.

I hope we are clear with this diagram

so let’s move forward

Before that we should take the

note of the formula which will surely help us to find the capacity of pump

which is required for the application.

PUMP HP

FLOW RATE (GPM) X

HEAD (FT.WG) X SPECIFIC GRAVITY OF WATER/3960 X EFFICIENCY OF THE PUMP

SP.GRAVITY OF

WATER:1

EFFICIENCY OF PUMP

:55 % TO 65%( assume )

So this formula will conclude

with how much amount of capacity does the system requires to uplift the fluid .

Well everything is known in

the formula except the head , head calculation is bit lengthy so lets take dive

into it.

From the figure of pump plant

room lets understand some terminology for calculation of head.

PUMP DISCHARGE LINE

PUMP DISCHARGE HEADER

CHILLER SUCTION HEADER

CHILLER SUCTION LINE

This is the line through which

water get discharged from pump and passed to the chiller.

CHILLER DISCHARGE LINE

CHILLER DISCHARGE HEADER

BYPASS LINE

PUMP SUCTION LINE

This is the line through which

water get discharged from chiller and passed to the pump.

So lets understand the requirement

of calculation

DIAMETER

FLOW

STRAIGHT LENGTH IN FEET

VALVES AND FITTINGS

HEAD LOSS FITTING(FT) OF

FITTINGS

So we will tabulate the

requirement for better understanding.

So lets start with pump discharge

line head calculation

So to calculate the head we

need diameter of pipe which is 10 inches(calculated by pipe design)

Flow rate of the pipe in GPM

which is obtained from the capacity of chiller say 2160 GPM.

Next is straight length of discharge

line in feet say 12 feet.

Valve and fitting have

different head loss assumption from reference books

So head loss are the loss of

heat which takes place due to obstacles in the flow of water which is valves

and fittings.

So adding both head loss due

to fittings and length of discharge line we will get total head .

HEAD LOSS IN FT./100FT so to

find this we will use a pipe sizer software.

Well after putting the pipe

size 10 inches

GPM flow rate we get head loss

2.13ft/100

Head loss or friction loss for

total head

2.13 x 344/100 =7.4 feet

Hope you got it similarly we

have to do it for others and we will get the following data.

This is the line through which

water get discharged from pump and passed to the chiller.

This is the line through which

water get discharged from chiller and passed to the pump.

After that we have to add the

friction head loss and multiply it by 15% safety factor.

We will get head loss in feet

of w.g

Now as we are known with the

head we can use the following formula to calculate pump HP calculation.

PUMP HP

FLOW RATE (GPM) X

HEAD (FT.WG) X SPECIFIC GRAVITY OF WATER/3960 X EFFICIENCY OF THE PUMP

So we will get the capacity required

for fluid to be lifted to desired point using following method.

This is only for primary pump

in the same way we have to calculate for secondary pump system..

Hope this post was useful for

you…

please don`t enter any spam link in the comment box ConversionConversion EmoticonEmoticon