DUCT

DESIGN

The function of a duct system

is to transmit air from the air handling apparatus to the space to be

conditioned.

It act has a transporting

system from AHU TO CONDITIONED SPACE.

Well duct is very important

parameter in an air conditioning system, which act as supplying agent which

transmitted the treasury cold conditioned current suitable for human being.

Duct are the medium through which

desired cold or hot conditioned air is been supplied .

Well duct are used in the larger

space where the cooling box or air conditioner system is organised at particular

junction and been connected to different space where conditioned air is been

supplied via system called duct.

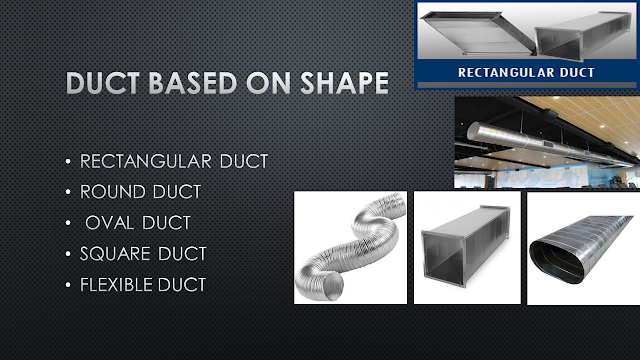

DUCT BASED ON SHAPE

Duct are been used depending on various

requirement and due to this there are various shapes of duct available in the

market.

We will surely dive deep in this topic but

before that we must go forward with the thing we need to understand for our

betterment.

But we will have a shallow

overlook on the shapes of the duct so we will be less curious about it.

Well as you can see that there are five

duct shapes which is been mentioned in this article but there are most found duct

shape in the market.

Basically square,round,rectangular oval ,etc

are the rigid ducts which are find everywhere where there is a presence of

cooling environment.

This duct are been chosen depending on

various calculation that we are going to have glimpse today.

But round and oval shape duct are generally

used where there is no space issue over the false ceiling.

Well as you know, generally the ducts are

been hided from us with the help of false ceiling it might be in big shops

,malls air ports etc

Round and oval duct are used because it

has less friction loss while flowing or moving the cool air.

But if space is consider than we get

inclined towards rectangular duct but now days capsule type of duct which is

combination of round and rectangular are been used as it is less space consuming

and less friction too but increase the financial stance.

If we look at flexible duct , this are the

duct which has a flexible wire covered with silver coated cover generally used

where the rigid duct are less possible to connect.

Flexible duct as the name is a flexible product

which can be turn and twisted to supply conditioned air.

It is generally used where changes occurs in

the site and the rigid duct are less possible to use in a very small and

critical space but if twisted more there are higher chances of losses so recommended

less..

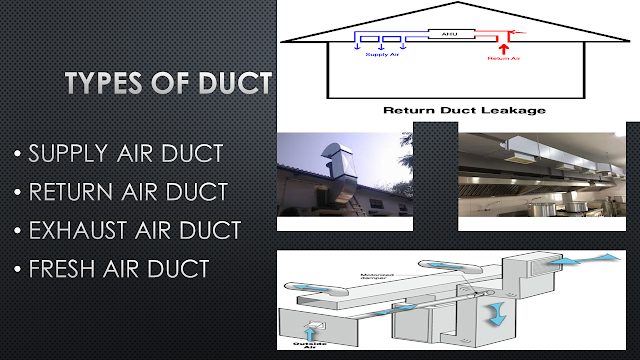

TYPES OF DUCT

Basically there are 4 types which are

common in the industry of HVAC

Well lets move where are been this duct

used for ….?

Supply air duct are

used where cold current of conditioned air is been supplied…

Return air duct

are the duct which extract or take away the used conditioned air in the

conditioned space , this used air is been sucked by the air conditioner system

by creating a negative suction energy with high speed motors.

Exhaust air duct

are generally used in place where the air in the surrounding are non inhalable

and hence it has to be removed and make a provision for fresh air ,at which

such duct are been used .

Fresh air duct are

duct which make the provision for fresh air in an area where the non inhalable gas

has been removed and fresh air take that space …

DUCT MATERIAL

Well duct plays a very important role in

transmitting the conditioned air to required space ,it is also necessary to

look after the material which is been used in the duct work so that it can withstand the high pressure and various temperature of the conditioned and non conditioned air.

So lets have a look at the types of material

used in duct making.

Galvanised steel

Galvanised mild steel is the

standard and most common material used in fabricating duct work because the zinc

coating of this metal prevents rusting and avoids cost of painting.

Aluminium (Al)

Aluminium duct work is lightweight and quick to install. Also,

custom or special shapes of ducts can be easily fabricated in the shop or on

site.

Flexible ducting

Flexible ducts (also known as flex) are typically made of

flexible plastic over a metal wire coil to shape a tube.

Flexible duct is very convenient for attaching supply air

outlets to the rigid duct work.

It is commonly attached with long zip ties or metal band

claps. However, the pressure loss is higher than for most other types of ducts.

Fabric ducting

The term fabric duct air dispersion system would

be the more definitive name. However, as it often replaces hard duct work, it is

easy to perceive it simply as a duct.

Usually made of polyester material, fabric ducts can provide a more even

distribution and blending of the conditioned air in a given space than a

conventional duct system.

What are fundamental requirement of DUCT

Energy efficiency : Faulty

duct work can result in air loss . This can increase your energy bills as your

AC works to accommodate for the loss.

Better comfort : uneven

cooling is a common sign of faulty duct work, so having good duct work helps

ensure better comfort inside your home.

Good air quality :just as

air can escape from your duct work, outdoor air can get in through the same

holes and cracks. This means particles and even exhaust fumes from other large

household appliances can enter your air flow and decrease the quality of your

indoor air.

So after having the basic knowledge of ducting we are

eligible to move ahead with designing of the duct.

There are various aspect which need to be taken

care while designing the duct for any project.

A good designer always gives a good product to the

society with most efficient knowledge obtained in the field of HVAC .

A good designer should take care of Energy

efficiency, Better comfort and Good air quality .

So taking into it into consideration lets move with

the designing procedure.

DUCT DESIGN

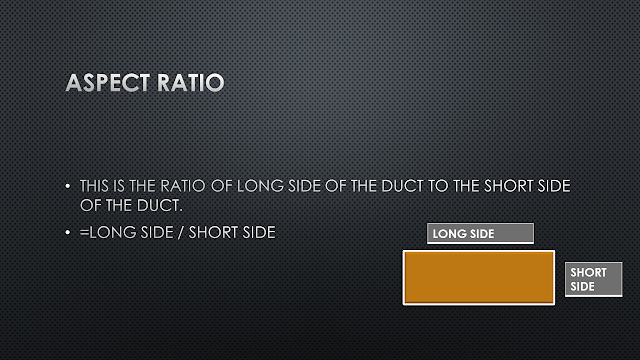

Aspect ratio

:this is the ratio of long side of the duct to the shorter side of the duct.

As aspect ratio increases more metal

surface is required for the duct of the same cross section.

So after reading above line we will be not

clear with it ,obviously it need an explanation.

So don’t worry we will have a clear picture

by having an example from above slide.

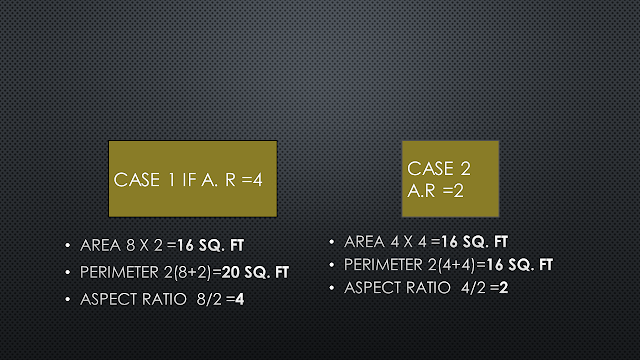

As we can see that there are two cases

In which cross section of the both

cases are same

But perimeter of case 1 is more than that

of case 2…

In case 1 ,Aspect ratio is 4

In case 2, Aspect ratio is 2

So as aspect ratio increases more the

metal surface of the duct required for the same cross section.

Hope we are clear with it.

Hence it is necessary that aspect ration

should be less than 4.

As the aspect ratio decreases ,less sheet

metal surface in contact with air results in decrease of the friction and

running cost of the project.

At the time of designing, we should try to

make the duct shape similar to square.

Now lets move on different types of method

used in duct design.

- EQUAL FRICTION METHOD OR CONSTANT

PRESSURE METHOD

- VELOCITY REDUCTION METHOD

- CONSTANT VELOCITY METHOD

- STATIC REGAIN METHOD

Before

understanding this method it is necessary to understand the basic formula of continuity

equation.

So CONTINUITY EQUATION

Q=AV

Where, Q = flow rate of air in cubic feet

per minute CFM

A= cross sectional area of the duct

V= velocity of air in feet per minute FPM.

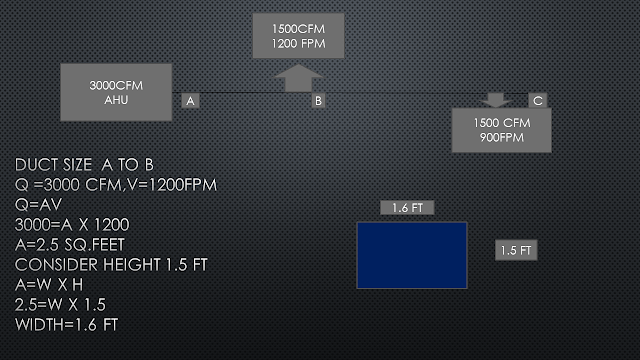

So let have an example to clear all the

doubt which may be arriving in our minds.

Well from the example we could find that ,

AHU consist of 3000 CFM which is the

quantity of air , and we assume velocity to be 1200 FPM .

So using the equation we get area of the

duct ….

So after understanding having a clear idea we will move

forward with different method.

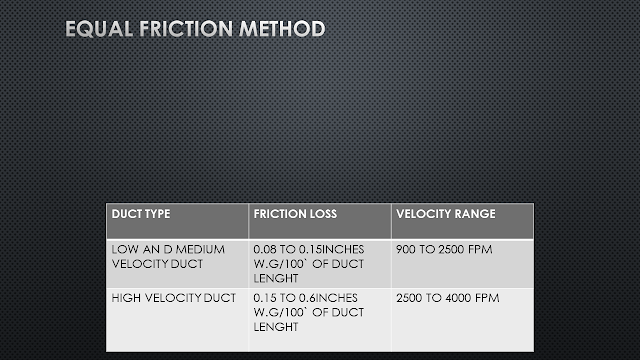

EQUAL FRICTION METHOD OR CONSTANT

PRESSURE METHOD

With this method ,same value of friction

loss rate per length of the duct is used to size each section of the duct.

The friction loss rate is chosen to result

in an economical balance between duct cost and energy cost.

A higher

friction loss results in a smaller ducts but higher fan operating cost.

This method is most universally used for

supply ,return, fresh and exhaust duct for low and medium pressure up to 4`` of

w,g.

Well after coming across above line you

might have basic introduction of what the equal friction method deals with .

Basically in this method we have to keep

the friction in duct while the air moves in it to be constant .

So lets take an example which surely

remove all the confusion!!!!!!!!!

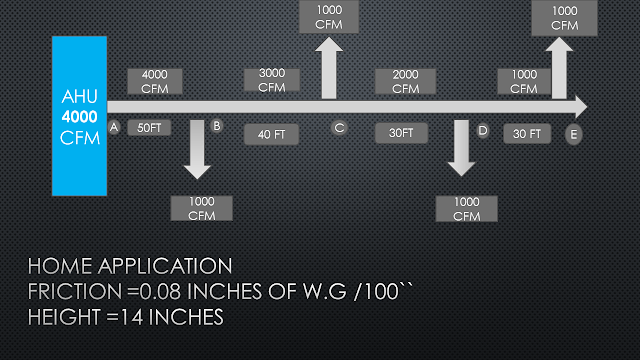

So lets take an example with a system of

4000 CFM capacity as shown in the figure., which also have some basic details

of application which is home, friction rate which is 0.08 inches of w.g /100``

and height of duct to be 14 inches according to available space over the false ceiling.

lets take an example at section A-B

Flow rate is 4000CFM

Friction loss is 0.08`` of W.G

So basically there are two ways we can

find out the duct area

Friction chart

so it is a graphical chart through which we get important parameter necessary for duct size.

It is basically air quantity in CFM which is on

vertical axis vs friction loss which is

in horizontal axis chart which is used to find the diameter area of the duct

from the chart having friction known and air quantity known

So lets find out diameter area for air

quantity 4000 CFM and friction loss 0.08`` of W.G

So we 24`` of diameter

So as we know diameter is 24`` and height

is 14`` of duct assumed.

So from the chart on horizontal line find

14`` and in that column find 24`` you will find from the chart 23.9``and 24.5 ``choose bigger no. i.e 24.5 and move towards left side in a row you will find 38`` which is your width .

Hence 14`` x 38`` is the area for section

A -B and so on for other section….

So that’s all about the manual or

frictional chart method so let move forward with software method.

Duct sizer software.

Just put the value of air quantity 4000

CFM , Head or friction loss 0.08`` of w.g, assumed duct height 14`` you will get above

results.

Carry on with other section and you will

get the following data.

ADVANTAGES

AUTOMATICALLY REDUCES AIR

VELOCITY IN THE DIRECTION OF AIR FLOW FOR SUPPLY AIR.

BALANCED DESIGNING WITH

RESPECT TO INITIAL AND RUNNING COST

QUICK AND EASY METHOD

IF THE DUCT LAYOUT IS

SYMMETRICAL NO DAMPERS REQ. FOR BALANCING.

DISADVANTAGES

NOT SUITABLE FOR LONG RUN

DUCT( DUCT MORE THAN 30` IN SINGLE SECTION)

VCD ( air controlling device) REQUIRE IF IT IS NOT

SYMMETRICAL.

VELOCITY REDUCTION METHOD

The size of the main duct is established by

selecting a velocity from the recommended range ,as done in the equal friction

method.

Therefore for every duct section taken out

,reduced velocity is selected based on previous experience with velocity and CFM,

and hence duct size are determined.

This method is though simple ,but not used

in actual practice because this is does not take into account relative pressure

losses in various branches.

CONSTANT VELOCITY METHOD

In this method the velocity throughout the

duct system is kept constant.

Initial selected velocity is very low ,compared

to other duct design methods.

This are generally for greater comfort

specially for high class projects where comfort is the priority.

The initial selected velocity is low ,as

friction is less and noise level is less.

STATIC REGAIN METHOD

The static regain method of sizing the

duct is most often used for high velocity systems with long ducts runs,

especially in large installation .

In this method the initial velocity of

main duct leaving the fan is selected in the range of 2500-4000 FPM.

After the initial velocity is selected,

the velocity in each successive section of the duct in the main run is reduced

, so that the resulting pressure gain is enough to overcome the friction losses

in the duct section.

As a result the static pressure is the same

at each junction balanced and simplified.

So before moving on we need to understand

what the static pressure is actually??

So lets take a example of air filled balloon

the air pressure which is exerting on the surface of the balloon is called as static

pressure and the flow with which the air flows inside the balloon is called

as velocity pressure.

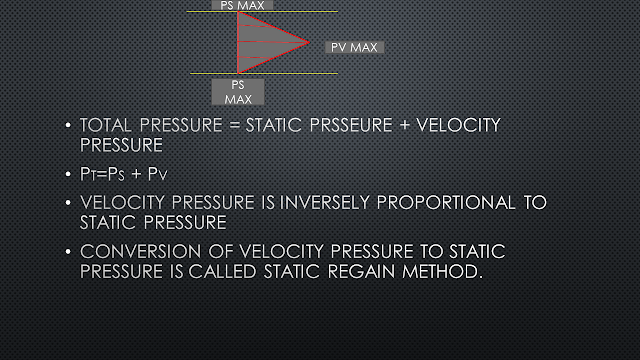

Now as per drawing above lets take a

example of a duct in which the air is flowing, so the pressure exerted by air

on the inner surface of the duct is called as static pressure .

Similary the air flowing with some

velocity is called velocity pressure.

And addition of both the pressure is

called as Total Pressure.

If you noticed the velocity pressure

in the duct is maximum at the centre of the duct whereas at the surface of the

duct it is almost zero.

And the static pressure at centre of the

duct is zero while at surface it is maximum.

Well static regain means converting the

velocity pressure to static is called as static regain method or gaining pressure

is called as static regain.

Well this method concentrate towards

increment on static pressure over frictional pressure losses and overcoming it.

MATHEMATICALLY,

STATIC PRESSURE = R X [(V1/4000)² - (V2/4000)²]

V1 = VELOCITY AT PREVIOUS SECTION OF THE DUCT

V2 = VELOCITY AT CURRENT SECTION OF THE DUCT

R = RECOVERY FACTOR, DEPENDS ON THE SHAPE OF THE DUCT FITTING THAT CHANGE VELOCITY (0.7 TO 0.9)

STATIC PRESSURE = R X [(V1/4000)² - (V2/4000)²]

V1 = VELOCITY AT PREVIOUS SECTION OF THE DUCT

V2 = VELOCITY AT CURRENT SECTION OF THE DUCT

R = RECOVERY FACTOR, DEPENDS ON THE SHAPE OF THE DUCT FITTING THAT CHANGE VELOCITY (0.7 TO 0.9)

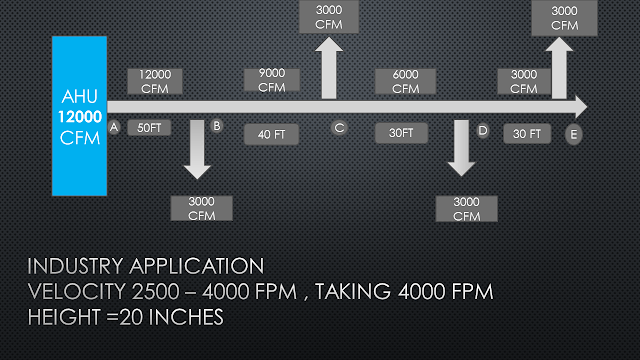

So lets take some example for method

understanding.

So let take section A-B

Taking velocity which is higher 4000 FPM ,duct

length 50 ft ,12000 CFM

So by using duct sizer we will get other

details

Well we get the following details of friction

loss or head loss in w.g per

100`` is 0.832 but duct length of section A-B is 50ft therefore friction per

duct length will be 0.832 x 50/100 we will get 0.416 for 50ft of duct.

In the first section we do not consider static

pressure because as per STATIC PRESSURE = R X [(V1/4000)² - (V2/4000)²] it

requires two different velocity.

Now lets take the second section from B-C

having 9000 CFM velocity assuming 3200 for 40ft length so lets put all data into

duct sizer.

Now we have to find using this details

whether the static pressure is greater then the friction pressure per

duct length.

PRESSURE = R X [(V1/4000)² - (V2/4000)²]

V1 = VELOCITY AT PREVIOUS SECTION OF THE

DUCT =4000FPM

V2 = VELOCITY AT CURRENT SECTION OF THE DUCT=3200FPM

R =0.9

V2 = VELOCITY AT CURRENT SECTION OF THE DUCT=3200FPM

R =0.9

As you can see that static pressure 0.324

is greater than friction pressure per duct length 0.224 hence this velocity is

selected.

If the static pressure will be less friction

pressure per duct length we have to choose different velocity…

Similarly we have to carry on this last until

and unless we get all value of duct size…

ADVANTAGES

SUITABLE FOR LONG AS WELL AS

SHORT RUN

NO BALANCING REQUIRED

ACCURATE METHOD

DISADVANTAGE

TIME CONSUMING METHOD

This are the four types of

methods which are used to find out duct size in which equal friction method is

mostly used for residential whereas static regain methods are used for

industrial .this are the most common method which are used to find the duct

size. hope we have a clear idea about duct sizing and all ducting related

topics.

please don`t enter any spam link in the comment box ConversionConversion EmoticonEmoticon