PIPE SIZING IN HVAC

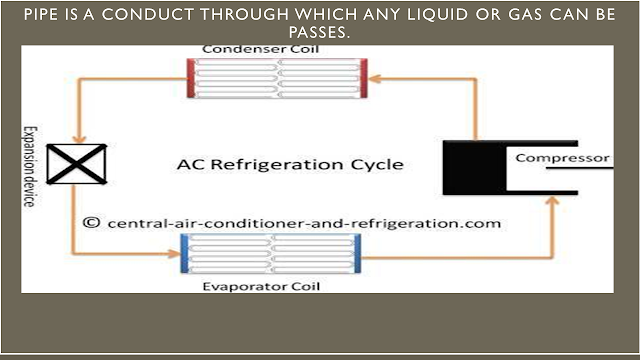

Pipe is a conduct or a medium through

which any liquid or gas can be passed.

Well similar to duct it is a kind

transferring medium through which gas or liquid is been proceeded.

Pipes are very important part

in transferring the required liquid or gas to required place with the presence

of pressurised pump system which maintains required pressure to flow the liquid

to desired point.

Well as we know that either it

may be cooling or heating of an area it is not possible and economical to place

a different cooling system everywhere hence pipes conduct and takes the responsibility

to transfer the liquid or gas medium to required point.

Well the responsibility of the

pipe are to supply the cool water and bring the hot water back to the system

and repeat this process continuously as an cycle.

AIR CONDITIONING PIPING SYSTEM

In an air conditioning system

the pipe which joins compressor ,condenser, expansion valve and evaporator

through which refrigerant is passed is called primary refrigerant.

Generally the pipe material

used in this air conditioning system are copper.

Well the copper which are used

are depending on the amount of capacity and the pressure resisting capacity of

an air conditioning system which are made of copper material ,which is soft

copper for up to 2 TR system and above 2

TR hard copper is used.

Well the above system where copper

is used are generally for air conditioning system.

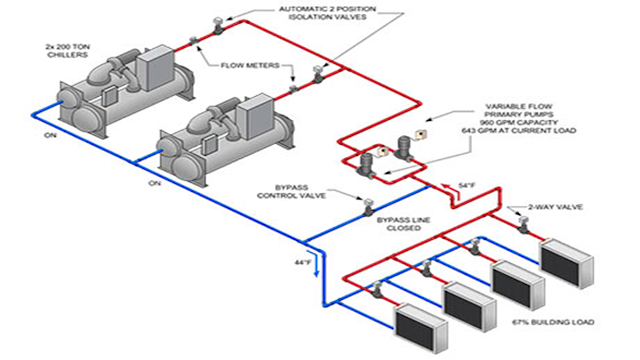

CHILLER PIPING

SYSTEM

In chiller system there is

additional piping which joins pump, FCU or AHU and chiller in which chilled water is been

supplied is called as secondary chill water piping.

CHILLER CONDENSER PIPING

SYSTEM

The condenser piping are

generally seen in water cool chiller system which connects pumps, cooling tower

and shell and tube condenser is called open piping or hot water system.

MATERIALS IN

CHILLED WATER PIPING

In chilled water system there

are generally two type of material used

Mild steel M.S:

Black steel (low carbon steel)

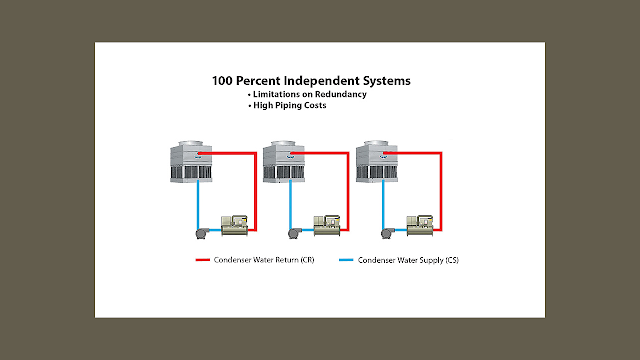

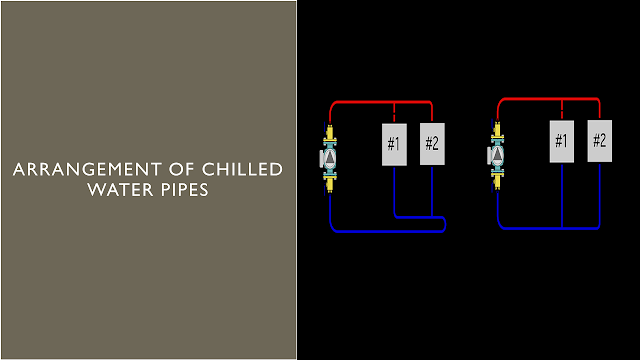

ARRANGEMENT OF CHILLER PIPING SYSTEM

Well chilled water pipes are

generally arranged in two ways:

TWO PIPE DIRECT

RETURN SYSTEM

Well have a look at the second

arrangement which is called as two pipe direct return system.

From figure you can see the

pumps are been connected to the AHU system via pipe connection.

Basically in this system blue

coloured chill water is been supplied to the AHU 1 and than to AHU 2 while taking away the used

or evaporated water again from AHU 1 and AHU 2 in red colour line.

Hence this system is not

hydraulically balanced because the amount of pressure absorb by the AHU 1 is

more compared to AHU 2 as we know the flow rate decreases with the coverage

length of fluid flowing in the path.

While the extraction of water

is also taken place at AHU 1 firstly and than at AHU2 hence this system is not

hydraulically balanced.

If the system is not

hydraulically balance there are chances of pipe getting leaks and reduce its capacity

to hold the pressure of water flowing in it.

Hence to overcome and maintain

hydraulically balance system we need to focus on proper systematic arrangement.

TWO PIPE REVERSE SYSTEM

Well have a look at the first

arrangement which is called as two pipe reverse return system.

From figure you can see the

pumps are been connected to the AHU system via pipe connection.

Basically in this system blue

coloured chill water is been supplied to the AHU 2 and than to AHU 1 while

taking away the used or evaporated water again from AHU 1 and AHU 2.

Hence the system is

hydraulically balanced and there are less chances of getting leakage due to

uneven pressure .

This is very important part in

arrangement , because it not only hydraulically balance but increases the life

of the whole system by contributing to avoid losses of financial bones of a

project.

CLASSIFICATION OF

PIPE

ACCORDING TO MAUNFACTURING

SEAMLESS PIPES(CONTINUOUS

PIPES WITHOUT WELDING JOINTS)

GENERALY USED FOR REFRIGERANT

PIPING TO AVOID LEAKAGE AND WITHSTAND HIGH PRESSURE UPTO 40 BARS)

WELDED PIPES (GENERALLY USED

FOR CHILLED WATER,HOT WATER,PLUMBING AND FIREFIGHTING)

ACCORDING TO CLASS

CLASS A OR SCHEDULE 20 OR LIGHT

DUTY

CLASS B OR SCHEDULE 40 OR

MEDIUM DUTY

CLASS C OR SCHEDULE 60 OR

HEAVY DUTY

ACCORDING TO LOCATION

ROOF ( VELOCITY 10FPS)

RISER(VELOCITY 7 – 10FPS)

FLOOR(VELOCITY 5 – 7 PFS)

MAX VELOCTY 15 FPS

MIN VELOCITY 1.5 FPS

This are the data from carrier

handbook data book.

Well maximum velocity which is

15 FPS (feet per second)is to avoid erosion and increase the life of the

system.

And minimum velocity in

chilled water should not be less than 1.5 FPS(feet per second) in any pipe.

In chilled water pipe sizing before

designing it is necessary to know what is the capacity of system.

As we know in normal air conditioning

system when heat load is calculated generally the term used is how much ton of

capacity ?

similarly a whole chilled water system also have capacity which is

also denoted in terms of tons of capacity or TR.

But to find the pipe size one

need to know the GPM of pump system .

So let find it!!!!!!!

CHILLED WATER

PIPES(CHILLER TO AHU)

FLOW RATE IN GPM

1GALLONS = 3.78 LTR

GPM=TR X 24/∆T

1 TR =2.4 GPM (IF ∆T IS 10)

CONDENSER COOLING

PIPES(CHILLER TO COOLING TOWER)

FLOW RATE IN GPM

1GALLONS = 3.78 LTR

GPM=TR X 30/∆T

1 TR =3 GPM (IF ∆T IS 10)

Well there are two case

If the pipe has to be sized for

chilled water system from AHU to chiller than 1 TR =2.4 GPM (IF ∆T IS 10)

If the pipe has to be sized for

chilled water system from cooling tower to chiller than 1 TR =3 GPM (IF ∆T IS 10).

PIPE SIZING METHODS

CONSTANT VELOCITY

METHOD

VELOCITY AND

FRICTION METHOD

This are the two methods which

are generally used in pipe sizing or pipe designing method…

CONSTANT VELOCITY METHOD

As the name suggest in this

method the velocity of the fluid assumed

to be constant which have different value for different location …

ROOF ( VELOCITY

10FPS)

RISER(VELOCITY 7 –

10FPS)

FLOOR(VELOCITY 5 –

7 PFS)

So lets take an example so to understand

more clearly…

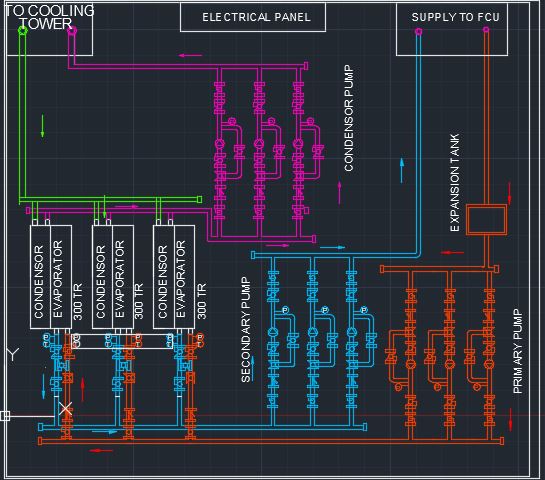

From the above diagram lets

have a look at the chilled water plant

Chiller which has two section

(condenser and evaporator).

CHILLER EVAPORATOR is the

space which consist of chilled evaporator coils in a shell and tube device

which chilled the water by absorbing the heat from it and this chilled water is

passed to the AHU or FCU via pump suction and discharge pressure.

CHILLER CONDENSER is the space

similar to evaporator space which consist of condenser unit where the refrigerant

heat is removed by exchanging the heat in condenser unit via supply of water cycle

in connection with pump line to the cooling tower where the hot water is cooled

.

So lets take an example of

four storey apartment having 900 TR cooling load i.e 540TR per floor

So lets find out the Total GPM

required..

1 TR =2.4 GPM (IF ∆T IS 10)

assuming std temperature difference

900 x 2.4=2160 GPM

AS we know that as per the

location velocity is constant

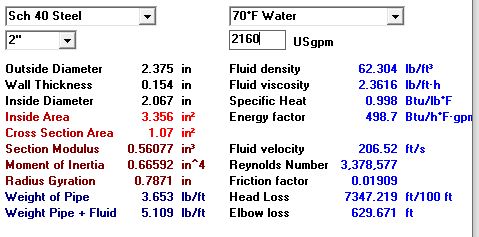

So lets used pipe sizer …by

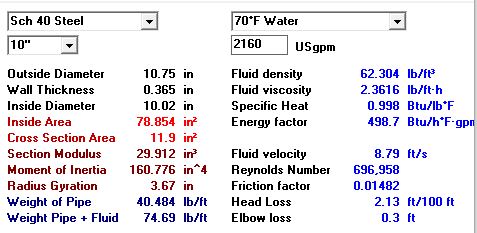

selecting the following

Pipe class schedule 40

70°F water

2160 GPM, we get the following data for riser pipe till

AHU 1

RISER

1)Q=2160GPM VMAX=10FPS

V= 8.79FPS(less than 10FPS) DIA=10``

hl=2.18``/100``

From above figure velocity is 8.79FPS for

10`` diameter if the velocity is more than 10`` it wont be accepted.

Similarly 2)Q=1620GPM VMAX=10FPS

V=6.59 fps DIA=10``

hl=1.2``/100``

3)Q=1080GPM VMAX=10FPS V=6.93fps DIA=8`` hl=1.8``/100``

4)Q=540GPM VMAX=10FPS V=8.66fps DIA=5`` hl=4.87``/100``

3)Q=1080GPM VMAX=10FPS V=6.93fps DIA=8`` hl=1.8``/100``

4)Q=540GPM VMAX=10FPS V=8.66fps DIA=5`` hl=4.87``/100``

This is all data for riser pipe size as

per the GPM , as the GPM decease the pipe size too decreases.

FLOOR

FLOOR(VELOCITY 5 –

7 PFS)

1)Q=540GPM VMAX=6FPS

V=6fps DIA=6`` hl=1.94``/100``

As every floor have same GPM so diameter

is also same having velocity lower than 6 FPS.

VELOCITY AND

FRICTION METHOD

As we know that in constant velocity method,

we avoid the friction consideration, for small size pipe and GPM it is suitable

but when it comes to heavy GPM the water tends to corroded the inner pipe

resulting in damage and leakage and ultimately break down of the project.

So to avoid it industry follows this

process … basically velocity and friction method is combination of both which

have certain condition when to used which method.

condition

1.velocity method

if diameter <=2``

velocity<=4fps

2.friction method

if dia >=2``

head loss<=4ft/100ft

well in this method velocity method is used

with diameter less than or equal to 2`` when the velocity is less than 4FPS ,

if its greater than we opt to friction method.

In friction method diameter should be

greater than 2`` and velocity is not the

concern here head loss is concerned which must be less than or equal to 4ft/100ft.

So lets take the same example.

VELOCITY AND FRICTION METHOD

RISER

1)Q=2160GPM

As we can see that with 2`` diameter

velocity is 206.52FPS , Which is against the condition1.velocity method =if diameter

<=2``,velocity<=4fps

Hence lets opt for friction method

1)Q=2160GPM DIA=10`` hl=2.18``/100``

This data is accepted according to the condition of friction method if dia >=2`` head

loss<=4ft/100ft

Similarly for others we get the following

data

2)Q=1620GPM DIA=8`` hl=3.9``/100``

3)Q=1080GPM DIA=8`` hl=1.8``/100``

4)Q=540GPM DIA=6`` hl=1.94``/100``

2)Q=1620GPM DIA=8`` hl=3.9``/100``

3)Q=1080GPM DIA=8`` hl=1.8``/100``

4)Q=540GPM DIA=6`` hl=1.94``/100``

FLOOR

4)Q=540GPM DIA=6`` hl=1.94``/100``

This is all about pipe sizing. Pipe sizing

is very important as the economical and safety condition need to followed for

optimised design of pipe size.

hope this article helped out to resolve your doubt....

please don`t enter any spam link in the comment box ConversionConversion EmoticonEmoticon